PRODUCT

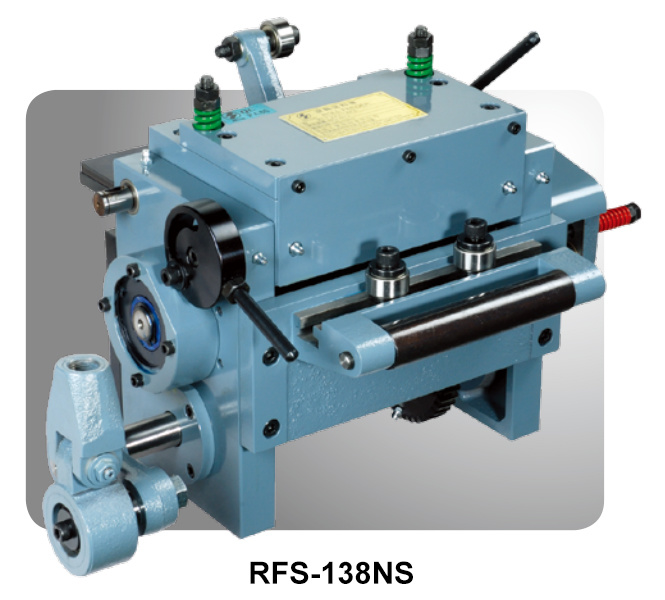

(RFS) Roller Feeder

- Details

- Parameter

- Video

-

- Commodity name: (RFS) Roller Feeder

- Commodity ID: 1118540846035783680

Roll Feeder

Roll FeederPatent No.57207 / Patent No.26277

Features:

1. High productivity: Suit mult-stage continuous product.

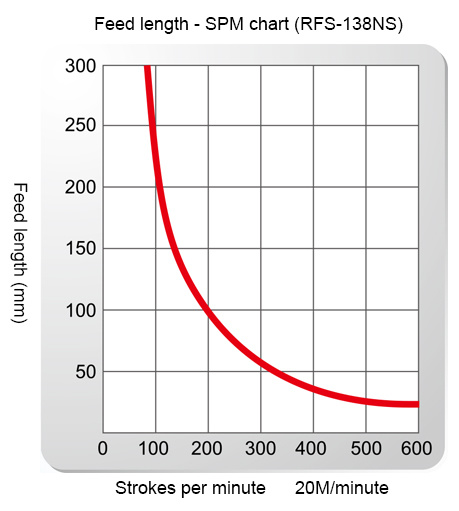

2. High speed: Reach 600 SPM.

3. Universal usage: *Easily adjust for different thickness and width.

4. Speciality: Special design for different material property(shapes, surfaces......etc.).

5. Practical and economical with simple mechanism.

6. High reliability with easy maintenance.

7. All power directly comes from press to save energy cost.

Feed Accuracy:

Depends on feed length and speed of press, the general accuracy is within ±0.05mm ( varied model has varied accuracy ). And can be even better up to ±0.01mm when die have pilot pin to centralize material automatically.

Type:

1. Single Type: Good for coil material. (Thickness above 0.15mm) For make single process or multi-process product.

2. Double Type: Good for coil material. (Thickness under 0.15mm) For make short pitch single process or multi-process product.

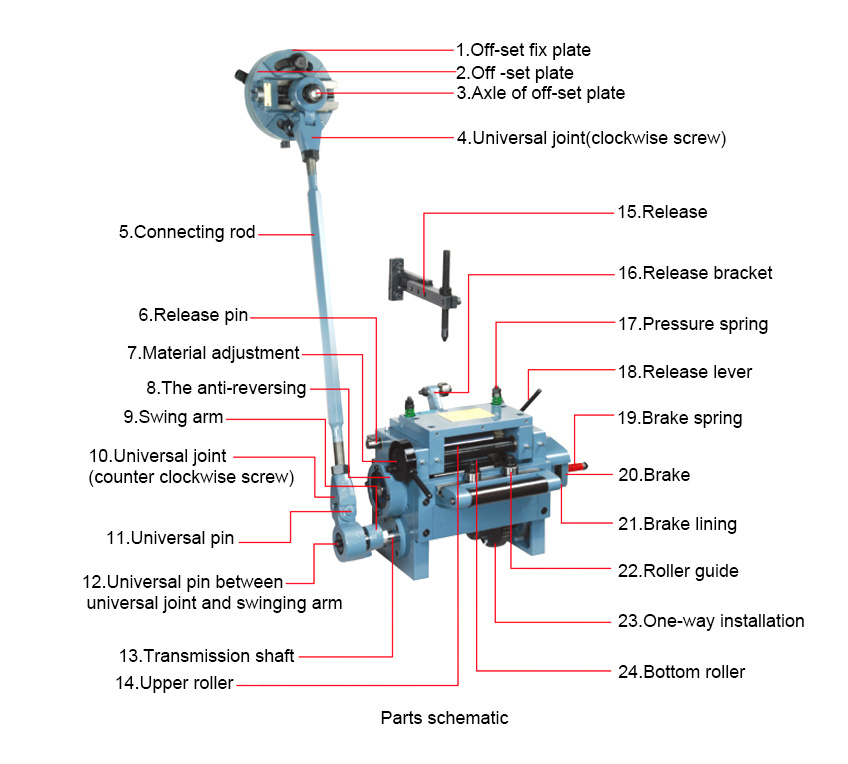

Mechanism Features:

1.One way clutch

a. Made of tungsten carbide steel on the contacting surface to keep rigidity, precision and durability.

b. The gear is hardened to HRC 60° and ground to the best transmission accuracy.

2.Roller

a. High feed accuracy at exact positioning with hollow roller of less weight and lower inertia.

b. Hard chrome plated heat treated to HRC 60° and ground for the best rigidity and durability.

3.Disk Brake

a. Apply the best brake lining to have accuracy, durability, and rigidity.

4.The Anti-reversing Device

a. The structure is same as the one way clutch. It can precisely control the lower roller which will not reverse even for long time used with highly stability and precision.

b. Well protection and location to avoid the brake sliding to lost accuracy by wasted splash oil during running.

c. Smooth running to lowest operating heat.

d. Super hard alloy and rolling post have been used to extend using lifetime.

e. The action of the rolling posts is by circular movement,not like the four guided posts moving in straight line. So it will not be stuck.

f. Less friction force to reduce the driving torsion to extend the transfer structure lifetime.

g. Equipped with anti-reversing device can upswing feed speed.

h. It's special structure increased using lifetime.

i. All models equipped with disk-brake and anti-reversing devices to become double location brake system. It can upswing high speed stabilization.

5.Netting Property

a. Directly transmit lower roller to avoid gear backlash to make sure feeding accuracy.

b. Amplify pitch adjust ratio to suit short pitch product like kinds nets and wipers.

6.Special Roller

a. Polyurethane upper roller: Avoid roller mark scratch on material surface.

b. Adjustable rollers: Adjust rollers to suit different width material to feed by gripping mateial sides.

c. All shapes rollers: Can ODM all shapes material like round, rectangle....etc.

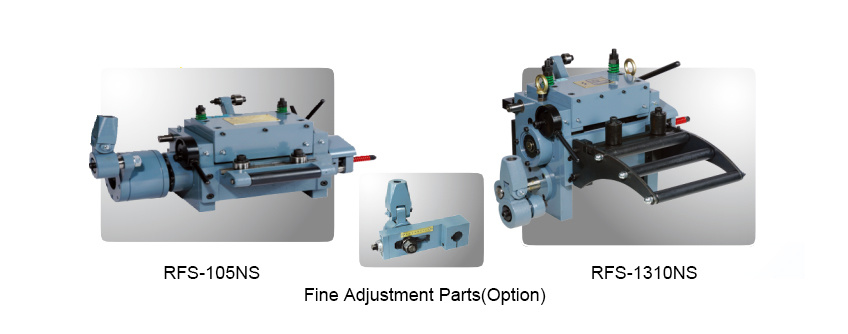

7.Fine Adjustment Device

a. Used to shorten feed length adjusting time.

8.Staged Connecting Rod

a. Used for quickly adjust material line height.

-

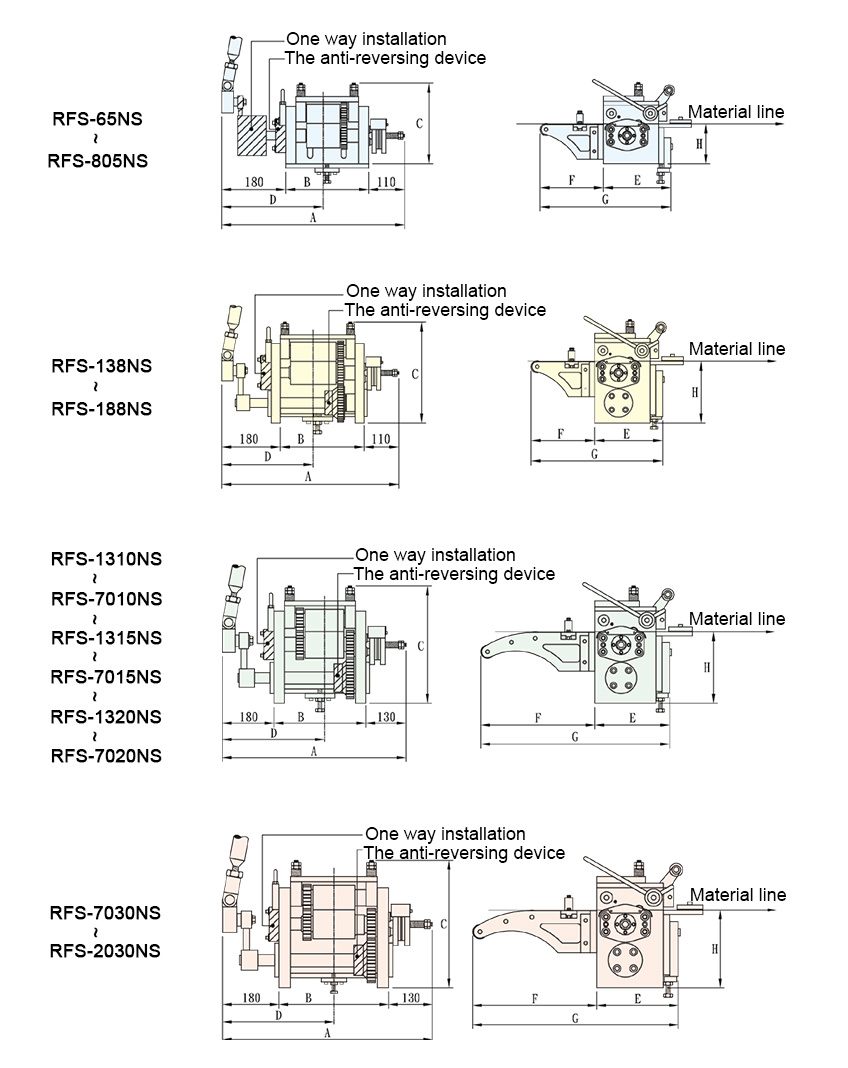

Model Roll

Width

(mm)

Max. Feed

Length

(mm)

Material

Thickness

(mm)

Material line

height

(mm)

Capacity of

press

(ton)

Dimensions(mm) Weight

(kg)

A B C D E F G H RFS-65NS 60 50 0.1-1.6 55-100 5-20 497 207 250 272 200 95 295 120 57 RFS-105NS 100 50 0.1-1.6 55-100 5-20 537 247 250 292 200 95 295 120 64 RFS-205NS 200 50 0.1-1.6 55-100 20 637 347 270 342 220 125 345 120 87 RFS-305NS 300 50 0.1-1.6 55-100 40 737 447 270 392 220 125 345 120 103 RFS-405NS 400 50 0.1-1.6 55-100 60 837 547 270 442 220 125 345 120 121 RFS-505NS 500 50 0.1-1.6 55-100 80 937 647 270 492 220 125 345 120 141 RFS-605NS 600 50 0.1-1.6 55-100 110 1037 747 270 542 220 125 345 120 161 RFS-705NS 700 50 0.1-1.6 55-100 110 1137 847 270 592 220 125 345 120 181 RFS-805NS 800 50 0.1-1.6 55-100 110 1237 947 270 642 220 125 345 120 201 RFS-138NS 130 80 0.1-1.6 60-120 10-60 535 275 310 276 200 95 295 185 76 RFS-188NS 180 80 0.1-1.6 60-120 20-60 605 345 310 311 200 380 325 185 84 RFS-1310NS 130 100 0.1-3.5 70-140 40-60 618 308 410 349 272 380 632 241 142 RFS-2010NS 200 100 0.1-3.5 70-140 40-80 688 378 410 384 272 380 632 241 155 RFS-3010NS 300 100 0.1-3.5 70-140 60-160 788 478 410 434 272 380 632 241 182 RFS-4010NS 400 100 0.1-3.5 70-140 80-260 888 578 410 484 272 380 632 241 200 RFS-5010NS 500 100 0.1-3.5 70-140 110-260 988 678 410 534 272 380 632 241 220 RFS-6010NS 600 100 0.1-3.5 70-140 160-260 1088 778 410 584 272 380 632 241 240 RFS-7010NS 700 100 0.1-3.5 70-140 160-260 1188 878 410 634 272 380 632 241 260 RFS-1315NS 130 150 0.1-3.5 70-140 40-60 618 308 410 349 272 380 632 241 143 RFS-2015NS 200 150 0.1-3.5 70-140 40-80 688 378 410 384 272 380 632 241 156 RFS-3015NS 300 150 0.1-3.5 70-140 60-160 788 478 410 434 272 380 632 241 181 RFS-4015NS 400 150 0.1-3.5 70-140 80-260 888 578 410 484 272 380 632 241 201 RFS-5015NS 500 150 0.1-3.5 70-140 110-260 988 678 410 534 272 380 632 241 221 RFS-6015NS 600 150 0.1-3.5 70-140 160-260 1088 778 410 584 272 380 632 241 241 RFS-7015NS 700 150 0.1-3.5 70-140 160-260 1188 878 410 634 272 380 632 256 261 RFS-1320NS 130 200 0.1-3.5 70-140 40-60 618 308 430 349 272 380 632 256 146 RFS-2020NS 200 200 0.1-3.5 70-140 40-80 688 378 430 384 272 380 632 256 159 RFS-3020NS 300 200 0.1-3.5 70-140 60-160 788 478 430 434 272 380 632 256 184 RFS-4020NS 400 200 0.1-3.5 70-140 80-260 888 578 430 484 272 380 632 256 204 RFS-5020NS 500 200 0.1-3.5 70-140 110-260 988 678 430 534 272 380 632 256 224 RFS-6020NS 600 200 0.1-3.5 70-140 160-260 1088 778 430 584 272 380 632 256 244 RFS-7020NS 700 200 0.1-3.5 70-140 160-260 1188 878 430 634 272 380 632 256 264 RFS-2030NS 200 300 0.1-3.5 100-190 60-160 720 410 480 485 317 380 677 298 223 RFS-3030NS 300 300 0.1-3.5 100-190 80-200 820 510 480 535 317 380 677 298 251 RFS-4030NS 400 300 0.1-3.5 100-190 80-200 920 610 480 585 317 380 677 298 279 RFS-5030NS 500 300 0.1-3.5 100-190 110-260 1020 710 480 635 317 380 677 298 307 RFS-6030NS 600 300 0.1-3.5 100-190 110-260 1120 810 480 685 317 380 677 298 335 RFS-7030NS 700 300 0.1-3.5 100-190 110-260 1220 910 480 735 317 380 677 298 363 Remark: Capacity of press is for reference only.

-