Contact Information

Tel: 86-512-57603979(Representative Number)

Tel: 886-2-2902-3186(Representative Number)

E-mail: kslc@retain.cn

Address: Building B, No. 38, Hengtang Road, Huagiao Town, Kunshan City, Jiangsu Province

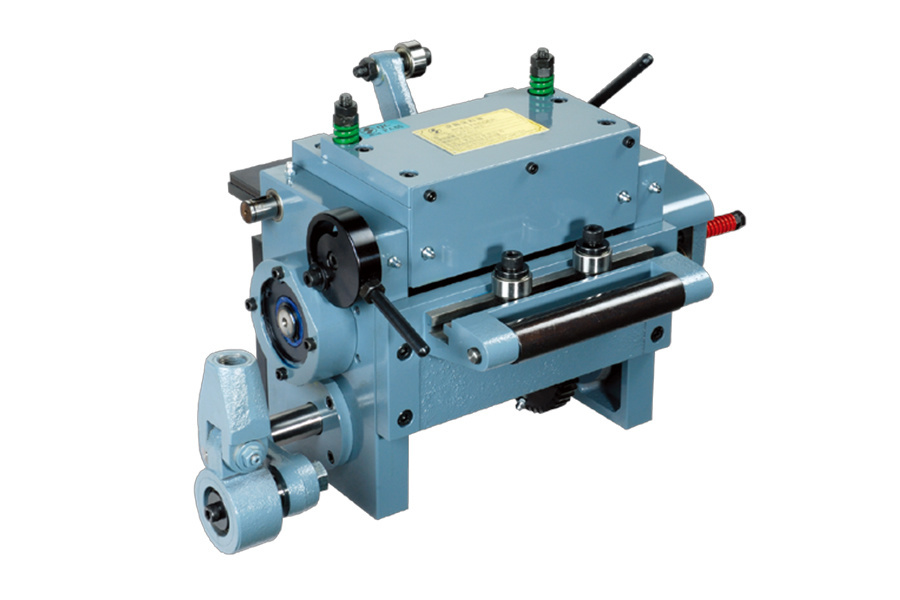

(NLF1 type) Three-in-one leveling feeder

Keywords:

- Details

- Specifications Chart

- Real-life video

-

- Commodity name: (NLF1 type) Three-in-one leveling feeder

Product Name: (NLF1 type) Three-in-one leveling feeder

Product Number: 1100350427447840768

Features:

1. High rigidity mechanical structure, combined with high-efficiency servo motor control, ensures feeding accuracy.

2. The structural design and NC electrical control are mainly based on ergonomics.

3. During operation, it can automatically monitor materials, ensuring the connection between the feeder and the press is reliable, making operation simple and safe.

4. The upper and lower rollers of the leveling device adopt a flip-up design, making maintenance easy.

5. The height of the feeding line adopts a screw lifting mechanism design, making it easy to adjust the height.

6. The material coil device uses hydraulic expansion, eliminating the need for manual material feeding, saving manpower, and enhancing safety.

7. Optional cart device can further save manpower during material coil handling, enabling one-person operation.

8. The material rack, leveling machine, and feeder are integrated, saving space.

-

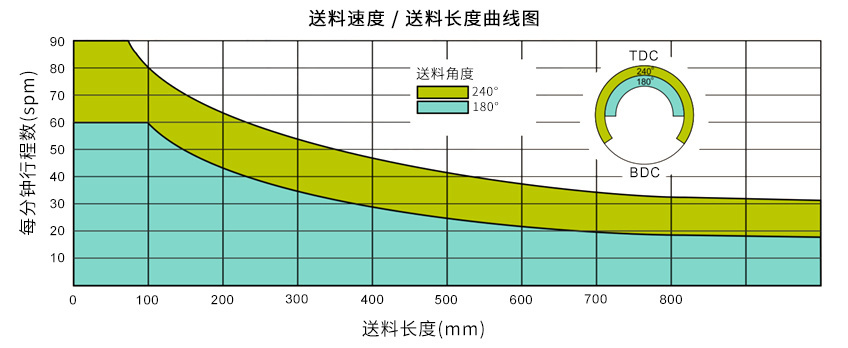

Specifications

NLF1-A Correction Capacity Table

NLF1-B Correction Capacity Table

Note:

1. The correction capacity chart is based on the tensile strength of (SPCC) 28-40kgf/mm² (JIS G3141)

2. SUS304-1/4H (Tensile strength 52kgf/mm², hardness HRB90° or less -JIS G4305), the maximum material width is 1/2 of the above table

-

Leave a Message