Contact Information

Tel: 86-512-57603979(Representative Number)

Tel: 886-2-2902-3186(Representative Number)

E-mail: kslc@retain.cn

Address: Building B, No. 38, Hengtang Road, Huagiao Town, Kunshan City, Jiangsu Province

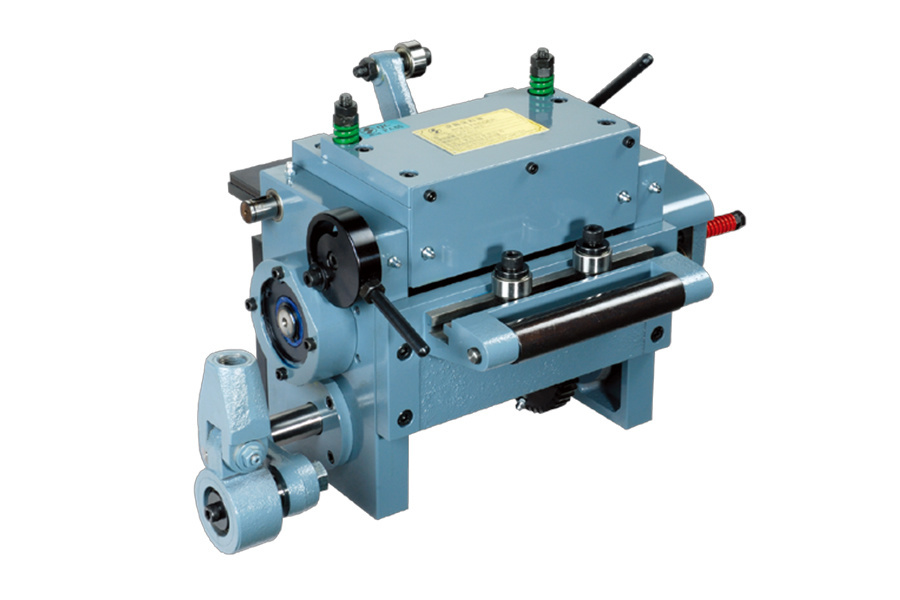

(SAF type) roller feeder

Keywords:

- Details

- Specifications Chart

- Real-life video

-

- Commodity name: (SAF type) roller feeder

Product Name: (SAF type) Roller Feeder

Product Number: 1100350419902287872

Leicheng Industrial adheres to the principles of high quality, high efficiency, and high technology, constantly innovating and improving, developing high-stability, easy-to-operate NC feeders, accelerating the arrival of high-return, high-competitiveness, and low-investment technology industries, providing a reliable and stable production environment for those engaged in stamping processing, to manufacture higher quality products.

Features:

1. High-precision feeding:

In response to the arrival of high-tech industries, using a computer closed-loop feedback control system and a high-sensitivity decoder, the accuracy is ensured within ±0.03mm (accuracy varies depending on the model).

2. Programmable feeding function:

40 different feeding lengths can be input, each with 999 stamping times, meeting the processing and production of special products (optional).

3. User-friendly manual mode:

Three suitable manual speeds can be input, making it easier for users to operate and accurately feed the material into the mold for positioning.

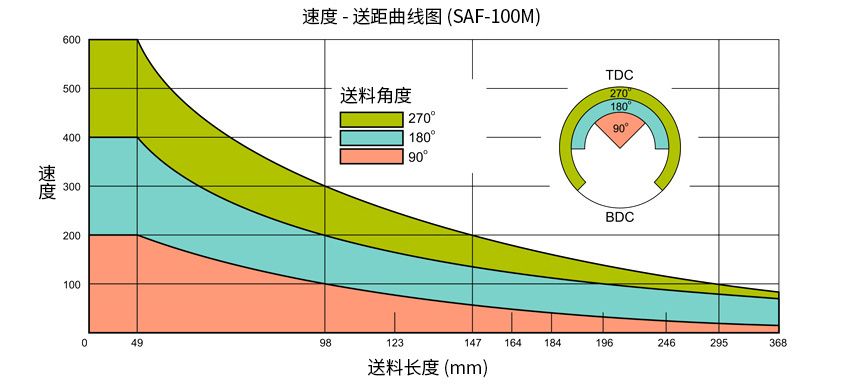

4. High-efficiency relaxation device:

With the cam signal of the punch press and simple material thickness adjustment, the relaxation angle can be quickly set.

5. Control panel function:

The operation panel has function keys for feeding length, number of times, speed, and angle, which can be set arbitrarily, quickly and accurately. The feeding length can be from 0.01 to 9999.99 mm.

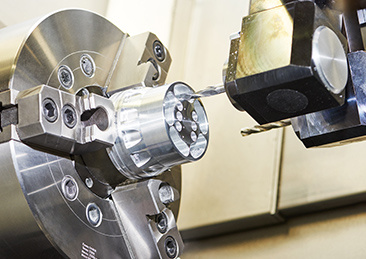

6. Feeding mechanism:

The roller adopts a hollow type, light weight, small rotational inertia, surface hardness HRC60° hard chrome plating, wear-resistant, and long life.

7. Suitable for stamping processing with varying material thickness, width, and long-size feeding.

-

-

Next

Leave a Message