Contact Information

Tel: 86-512-57603979(Representative Number)

Tel: 886-2-2902-3186(Representative Number)

E-mail: kslc@retain.cn

Address: Building B, No. 38, Hengtang Road, Huagiao Town, Kunshan City, Jiangsu Province

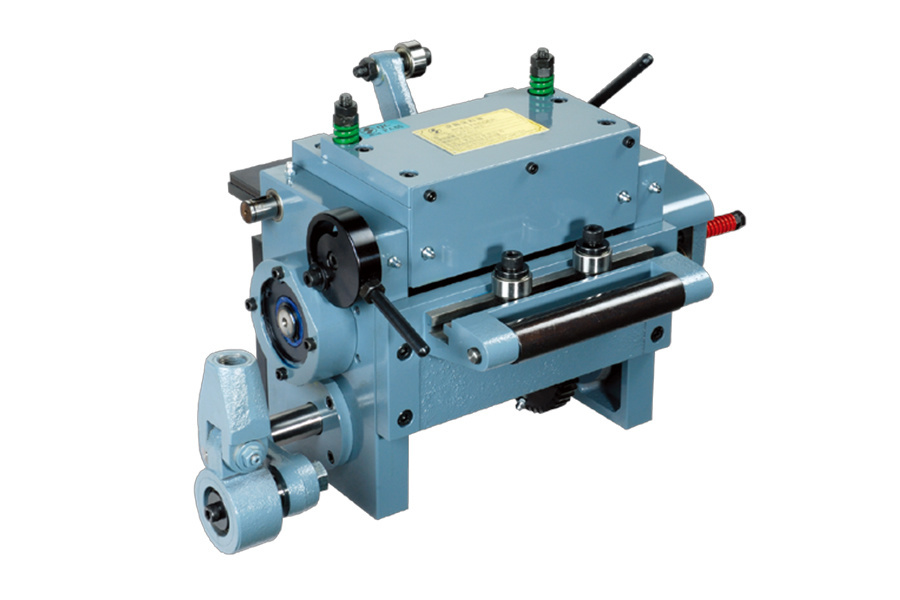

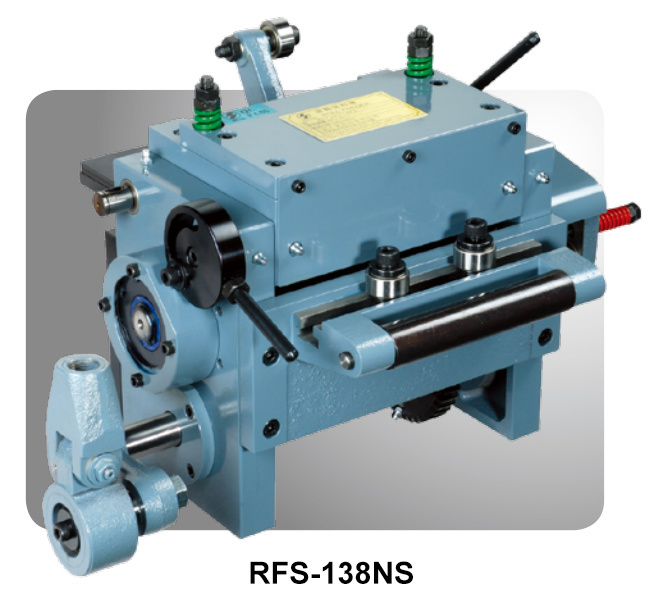

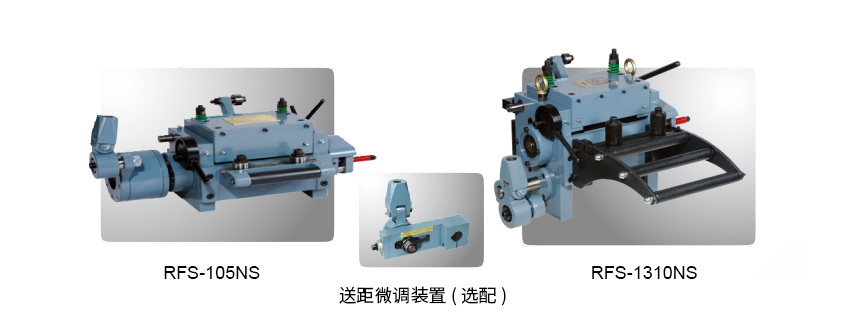

(RFS type) roller feeder

Keywords:

- Details

- Specifications Chart

- Real-life video

-

- Commodity name: (RFS type) roller feeder

Product Name: (RFS type) Roller Feeder

Product Name: (RFS type) Roller Feeder Product Number: 1100350412298014720

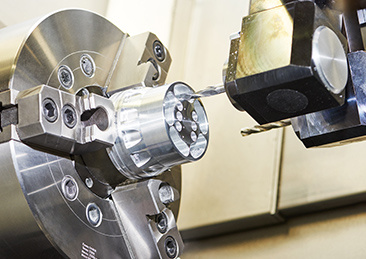

Roller Feeder

New Type No. 57207 / New Style No. 26277

Advantages of Roller Feeder:

1. Productivity: Allows for continuous processing of multiple tasks.

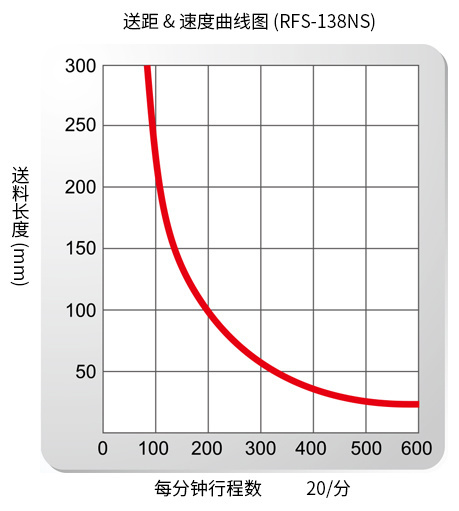

2. High Speed: Up to 600 times per minute.

3. Versatility: Regardless of material width and thickness, simply adjust the feeder to match the mold for easy use.

4. Speciality: Can be designed and manufactured according to customer material properties (special-shaped materials, bright electroplated plates, and various special materials).

5. Simple structure, economical and practical.

6. Low failure rate, easy maintenance.

7. Direct drive from the punch press, no power consumption.

Feeding Accuracy:

1. Varies depending on the number of revolutions and feeding length. Generally, the accuracy can be ±0.05mm (accuracy varies depending on the model). If a guide shoe is used for positioning, the accuracy can reach ±0.01mm.

Type:

1. Single: Suitable for coils (thickness 0.15mm or more), single products or continuous punching products.

2. Double: Suitable for coils (thickness less than 0.15mm), short-sized materials, single products or continuous punching products.

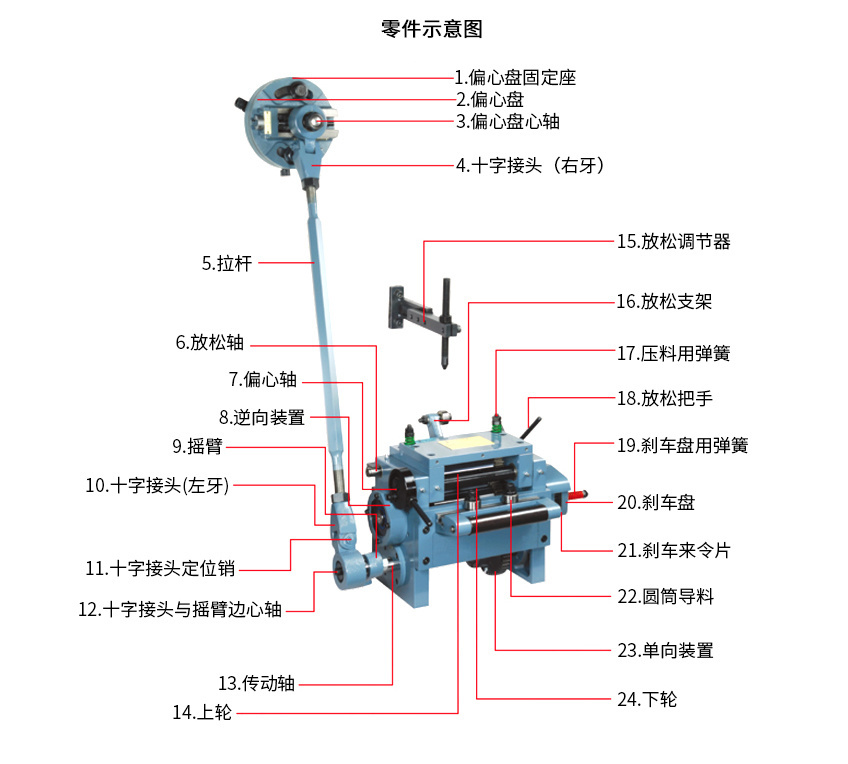

Eight Major Features of Roller Feeder:

1. One-way bearing

a. Embedded with super-hard alloy and combined with roller bearings, it has high wear resistance, safety, accuracy, and long service life.

b. The gear is heat-treated to HRC60°, then precisely ground, with high transmission accuracy.

2. Roller

a. Adopts hollow type, light weight, small rotational inertia, can stop instantly, ensuring feeding accuracy.

b. After heat treatment HRC60° hard chrome plating and grinding, high hardness, excellent wear resistance, and long service life.

3. Disc brake (general braking device)

a. Adopts high-grade clutch lining, with full contact on both sides, long service life, good stability, and high accuracy.

4. Reverse device

a. The structure is the same as the one-way device, which can accurately control the lower wheel. Even after long-term use, the lower wheel will not have any backward movement, with high stability and accuracy.

b. The brake will not fail and cause the lower wheel to reverse and the feeding distance to be inaccurate due to splashing residual oil during punching.

c. Not easy to generate high heat.

d. Equipped with super-hard alloy and rollers, not easy to wear.

e. The operation method is the circular motion of the roller, not the linear motion of 4 guide columns, so there will be no jamming phenomenon.

f. Small friction, the required transmission torque is relatively reduced, and the transmission mechanism is less prone to damage.

g. Equipped with a reverse device, which can significantly improve the feeding speed.

h. Special structure, increased service life.

5. Punching mesh characteristics

a. Directly drive the lower roller, eliminating backlash tolerance and ensuring feeding positioning accuracy.

b. Magnify the feed distance adjustment ratio, most suitable for punching products with short feed distances (such as punching mesh wipers...).

6. Special roller

a. PU upper roller: The material is not easily damaged during feeding.

b. Adjustable roller: Adjust the clamping material edge according to the material width to feed without damaging the material.

c. Various special-shaped rollers: such as round, flat wire materials, square materials...etc., special-shaped materials.

7. Feed distance fine-tuning device

a. Can shorten the feed distance adjustment time.

8. Multi-stage connecting rod

a. Quick replacement, convenient adjustment of the feeding line height, avoiding damage to the equipment.

-

Note: Punch press tonnage is for reference

-

Prev

Leave a Message