Contact Information

Tel: 86-512-57603979(Representative Number)

Tel: 886-2-2902-3186(Representative Number)

E-mail: kslc@retain.cn

Address: Building B, No. 38, Hengtang Road, Huagiao Town, Kunshan City, Jiangsu Province

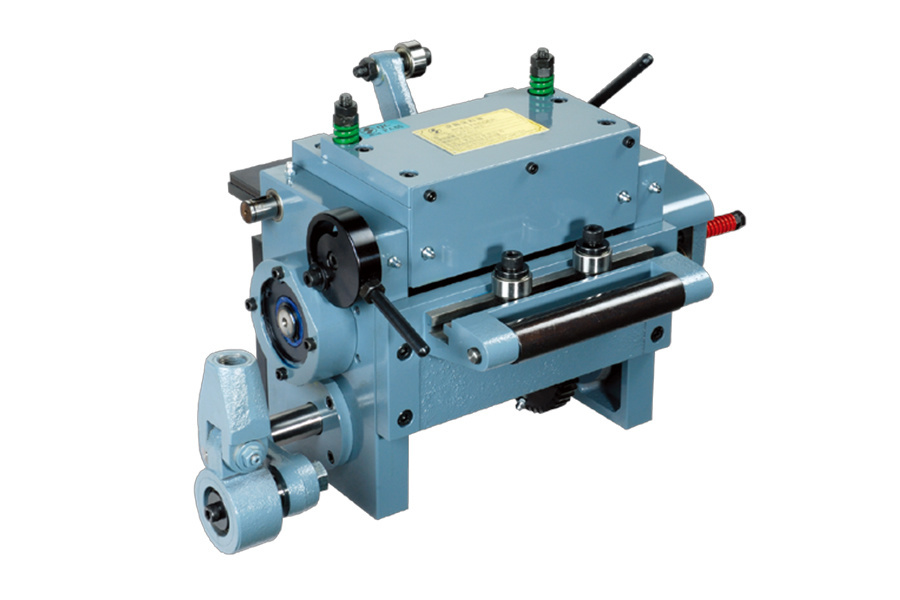

(GF-906N/GF-1512N) Clip-type feeder

Keywords:

- Details

- Specifications Chart

- Real-life video

-

- Commodity name: (GF-906N/GF-1512N) Clip-type feeder

Product Name: (GF-906N/GF-1512N) Clamp-type Feeder

Product Number: 1100350415187890176

Features:

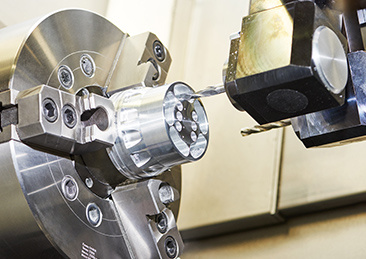

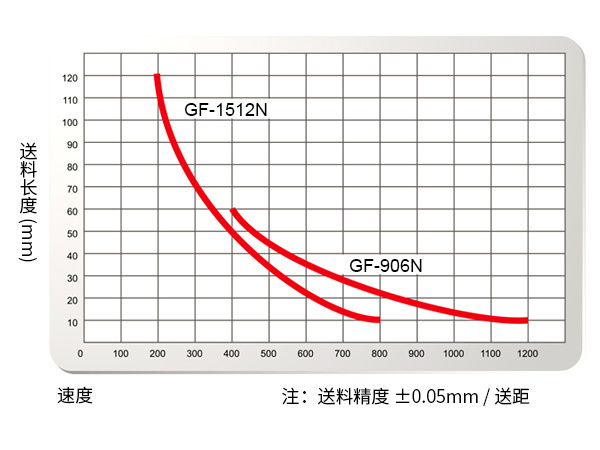

1. Suitable for high-speed processing and high-precision feeding of stamped products. (Feeding speed can reach up to 1,200 times per minute)

2. Quiet operation during mechanical operation, reducing workplace noise.

3. Will not leave any marks on the material surface, allowing manufacturers of electroplated materials, aluminum alloys, stainless steel, copper, iron, or secondary engineering products to obtain better stamping products.

4. All adjustments use a scale, making operation simple and stable; anyone can easily operate it.

5. The main body is integrally molded to avoid resonance during stamping that affects feeding accuracy.

Characteristics:

1. Plate thickness adjustment only requires rotating the scale according to the material thickness.

2. Relaxation device adjustment only requires rotating the scale according to the position of the guide pin in the mold.

3. Feeding length is adjusted using the crank eccentric amount (a gauge block method can also be used).

4. The upper pressure plate is pneumatic (pressure adjustable).

5. Felt is used for material cleaning.

6. When installing materials, the upper and lower pressure plates are opened and closed by a manual air valve switch.

7. Lubrication method: The gearbox, fixed seat drive, and main drive shaft are all oil bath type; other bearings are grease lubricated.

8. Can be connected to the cooling circulation oil system of the press to reduce the operating temperature of the mechanism. (Optional)

9. A clamping device that can simultaneously feed multiple material strips of different widths and thicknesses can be designed according to requirements.

-

-

Leave a Message