Contact Information

Tel: 86-512-57603979(Representative Number)

Tel: 886-2-2902-3186(Representative Number)

E-mail: kslc@retain.cn

Address: Building B, No. 38, Hengtang Road, Huagiao Town, Kunshan City, Jiangsu Province

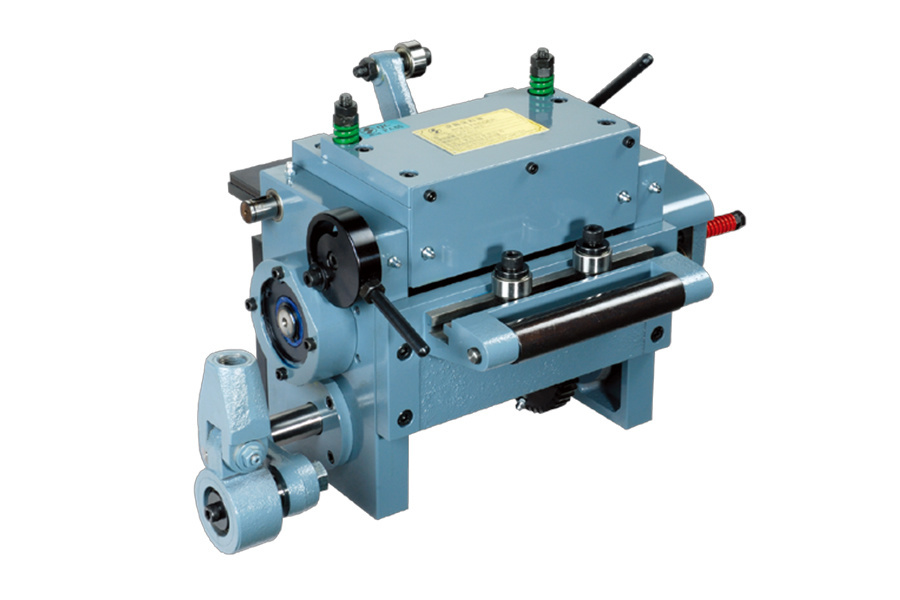

(GUL type) Two-in-one material rack leveling machine

Keywords:

- Details

- Specifications Chart

- Real-life video

-

- Commodity name: (GUL type) Two-in-one material rack leveling machine

Product Name: (GUL type) Two-in-one material rack leveling machine

Product Number: 1100350442807382016

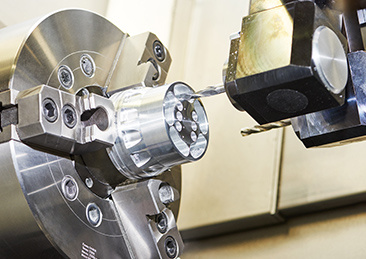

Two-in-one material rack leveling machine (a new generation of computer casing tool)

Features:

1. Combines the material rack and leveling machine into one, saving space.

2. Adopts a simpler operation method, easy to operate.

3. The upper working rollers adopt a turbine-type 4-point fine-tuning device, suitable for correcting processing quality requirements with high precision.

4. The roller material is bearing steel (SUJ2), heat-treated HRC60°, hard chrome-plated surface and then polished, high hardness, high wear resistance, and long life.

5. To ensure precision requirements, each leveling roller emphasizes the requirements of straightness, roundness, cylindricity, and concentricity to ensure its leveling effect.

6. Adopts a fixed fulcrum type to ensure that the guide rollers will not deviate when conveying the material.

7. The digital display allows for quick and accurate setting functions.

8. The leveling body is heat-treated and tempered before processing to avoid deformation and affect the leveling effect.

9. The expansion body and arc-shaped expansion claws of the material rack are made of FC25 cast iron to achieve high strength and concentricity requirements.

10. Adopts a stepless speed regulating device with a photoelectric sensor, avoiding roller marks.

11. Flip-up design, easy to clean, speed approximately 20 meters/minute.

Applicable to:

1. This two-in-one material rack leveling machine can be used with any feeding machine.

2. Also applicable to cutting production lines for long materials.

3. This machine is especially suitable for use in the computer casing industry, and many well-known manufacturers are currently using it.

4. Can be specially designed and manufactured according to customer's special requirements.

5. For stamping products with high surface requirements, such as galvanized sheets, electroplated sheets, fluorescent lamp reflectors, etc.

-

Note:

1. The correction capacity chart is based on the tensile strength of (SPCC) 28-40kgf/mm² (JIS G3141)

2. SUS304-1/4H (Tensile strength 52kgf/mm², hardness HRB90° or less -JIS G4305), the maximum material width is 1/2 of the above table

-

Leave a Message